Product categories

News center

Contact us

- Add: Room 5-1-1402, tou Jing Yue House, 50 Nan Xin Zhuang East Street, Huaiyin District, Jinan, China

- Tel: 13305313157 15588877119

- Fax:

- Email: 21345343@QQ.com

Product Numbers:

Price:面议

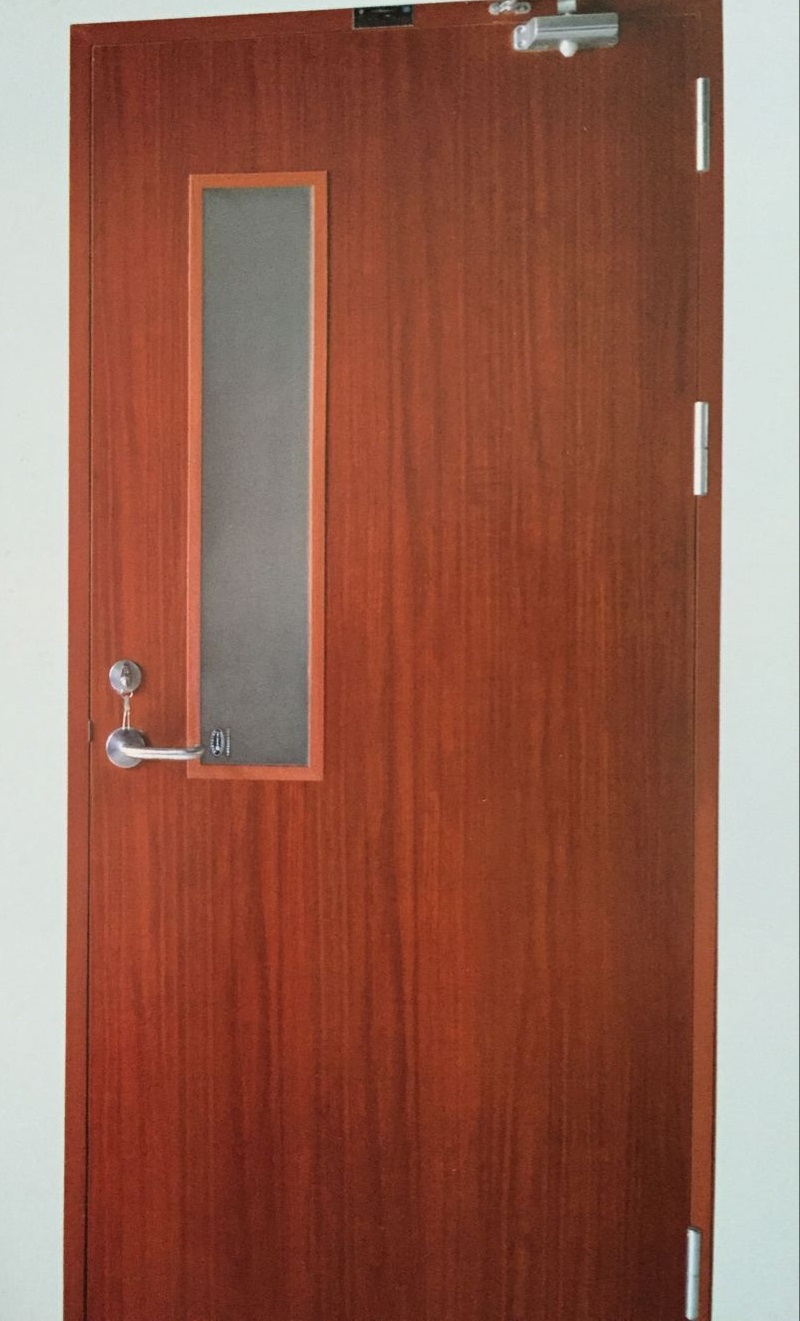

Product introduction:Wood fire doors are made of wood or wood products door frame, door frame, door panel, fire resistance to meet the“GB50045 -95” high-rise civil building design code of fire doors.

Wood fire door production requirements:

1. The door frame and the thickness of more than 50 mm should be used double tenon connection. Frame, fan assembly, the dovetail should be closely embedded, the application of glue bonding, and use glue wedge to tighten.

Note: In wet areas, grade I should use water-resistant Phenol formaldehyde resin, while Grade II should use semi-water-resistant URALDEHYDE resin.

2. When making plywood doors (including fiberboard doors) , the frame and the cross-bar must be on the same plane. The top layer, the frame and the cross-bar should be bonded under pressure. Should be in the horizontal ridges and up, down riser drilling more than two air holes, to prevent moisture degumming or heave.

3. The production quality of the door, should meet the following requirements:

(1) the surface should be clean or matte, and there should be no plane marks, burrs and hammering.

(2) the lines of the frame and the fan should meet the design requirements, and the cut angle and the stitching should be even.

(3) no degumming is allowed for small and short material glued doors and plywood or fiberboard doors. Plywood shall not be allowed to penetrate the veneer and closure.

(4) the permissible deviations in door fabrication shall be in accordance with table 5.1-1

4. When the condition is available, the door and frame should be assembled into a complete set, installed all the hardware, and then a complete set of installation. In general, you should first install the door frame, and then install the door fan.5.Wood fire doors made, should be immediately brush the bottom oil (dry oil) to prevent moisture deformation.

6. Door hardware installation, should comply with the following provisions:

(1) hardware installation should be complete, location appropriate, fixed and reliable.

(2) the upper and lower ends of the hinge should take 1/10 of the standing height, and avoid the upper and lower risers. The switch should be flexible after installation.

(3) all hardware shall be fixed with wood screws and shall not be replaced by nails. Should first hammer into 1/3 depth, and then screw in, not into the full depth. When using hardwood, should first drill 2/3 depth hole, hole diameter is 0.9 times the diameter of wood screw.

(4) it is not advisable to install a door lock at the junction of the Middle Head and the upright head.

(5) the door handle should be located below the center of the height of the door, 0.9-1.05 m from the ground.